cutting glass with diode laser

Some of our partners may process your data as a part of their legitimate business interest without asking for consent.

Therefore, it is essential to consult with the laser cutting machine's manufacturer or supplier to ensure the plastic material is suitable for laser cutting. Besides, the laser beam can be adjusted to suit different thicknesses, making it a flexible process that can be used for a variety of applications. Trim residual slivers or chips with square-jaw pliers if your glass cutters head doesnt have nibbling slots.

The properties of this material make the process straightforward, and it reduces the trial and error. This versatility makes laser cutting a popular choice in many industries, from automotive and aerospace to jewelry making and gift making, you can even start a small business selling laser-made products. Instead, the glass tip of the diode fiber is charred and heats up to between 500C to 900C via heating of the char by the diode laser light.

8. WebTo do a laser engraving on acrylic or glass you need a diode laser with wavelength 445 nm or a DPSS laser with 1064 nm wavelength of a Co2 laser with wavelength 10600 nm (10.6 um).

Open the Cut Settings Editor from the Cuts Layers Tab on the right-hand side of the screen. It can create precise shapes and designs for packaging, cosplay costumes, and props. WebAnswer (1 of 8): Yes, depending on the type and thickness of glass, and what you mean by cut. There is a lifetime warranty. It is commonly used in the fashion industry for cutting leather patterns, bags, and accessories. Keep in mind that different materials will require different settings, so you may need to adjust the settings for each new material you work with. The same physics-based assessment of cutting diodes summarized by Martin Kaplan, DMD. These lasers have a very poor coefficient of absorption of color Cutting with a diode laser requires activating the tip In essence, they function as electro-surgery units Robert Levine, DDS.

Open the Cut Settings Editor from the Cuts Layers Tab on the right-hand side of the screen. It can create precise shapes and designs for packaging, cosplay costumes, and props. WebAnswer (1 of 8): Yes, depending on the type and thickness of glass, and what you mean by cut. There is a lifetime warranty. It is commonly used in the fashion industry for cutting leather patterns, bags, and accessories. Keep in mind that different materials will require different settings, so you may need to adjust the settings for each new material you work with. The same physics-based assessment of cutting diodes summarized by Martin Kaplan, DMD. These lasers have a very poor coefficient of absorption of color Cutting with a diode laser requires activating the tip In essence, they function as electro-surgery units Robert Levine, DDS. When forward biased, the diode will inject electrons from the n-side into the gain region, and holes from the p-side into the gain region. Due to the release of high energy from atoms, laser beams are produced from the tube. Wearing goggles that block out the wavelength youre using is crucial.

1. Laser Lens Protective Cap: All You Need to Know, Laser Cutting Plywood: The Ultimate Guide. The optical power of the laser cutter determines how thick of an acrylic sheet it can cut. They are widely used for DIY projects and creating various products. It is in sync with the earlier assessment by the Honorary ALSC member Gordon Christensen, DDS, in his interview by Howard Farran, DDS, of DentalTown (see video clip below).

2018-2023 YoraHome. Expert advice from Bob Vila, the most trusted name in home improvement, home remodeling, home repair, and DIY.

You cannot use them for metal cutting. Class 1 laser system (fully interlocked), IEN OPTEC Femtosecond Laser Operational Demo. The computer program moves the laser head/module according to the requirement. With the xTool D1, you can create your own products, customize existing ones, and offer laser cutting and engraving services to your customers, which can be a source of additional revenue for your business. Offer not valid on previous purchases or pending orders. Your next move is perfectly clear: Time to place the glass youve cut and cross one more household repair from your to-do list. The radiation emitted from CO2 lasers is invisible as it is in the infrared region. Vector graphics are also scalable, which means they can be resized without losing quality.

If thats your situation, then we would recommend engraving tempered glass or acrylic. It's affordable, and you can add various attachments to expand its capabilities. All Rights Reserved. 1*20W Laser module ; 1*Spare protective window glass ; 1*3 Pin 80cm input cable ; 1*3 Pin 80cm input cable ; 1*Driver adapter; 1*power adapter; 1*Air Trachea6x4mm For serious DIY'ers, yes, this is a HUGE upgrade to most "10W output" laser diode systems. Consequently, they are very expensive. The process for cutting glass follows these simple steps: Thoroughly clean the glass you intent to cut.

Use high-quality design software to create your designs.

Clean the piece of glass with isopropanol alcohol or screen wipes this is an opportune moment to give your laser lens a quick clean too. The first thing to factor in is the glass thickness.

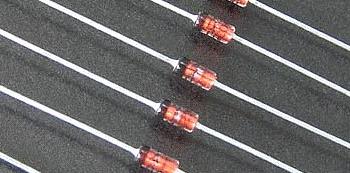

The diodes used for producing lasers are a bit different from common diodes. A laser kerf is the width of the cut made by the laser beam.

As the name suggests, diodes are used to create laser beams in this type of laser. When each of the tests finished, I could wash off the paint under running water to see exactly how the image looked. Laser type (pulse duration): picosecond, femtosecond All of which are useable with lasers and will allow you to try out glass engraving for yourself! Its worth noting that other kinds of glass usually require specific preparation and professional tools. It's always important to consult with a professional or the material manufacturer to determine the most appropriate cutting method for a specific material. Additionally, it is crucial to take precautions when cutting plastic materials as they can release harmful fumes when exposed to high temperatures. The beams are then passed through several bending mirrors and reflectors before converging at a single spot having a diameter in fractions of a millimeter through a convex lens. Open the Cut Settings Editor from the Cuts Layers Tab on the right-hand side of the screen.

The power of CO2 lasers ranges from 30 watts to 400 watts, making them suitable for cutting various thicknesses of non-metallic materials.

Discounts automatically applied at checkout.

The glass gets heated until the material literally evaporates, but this might cause deformation with some types of glass. To measure a replacement pane for a window frame, remove about inch from the length and width of the frames opening so the glass fits well once glazing is added to its edges. Reset speed and power500 mm/min and 30%. Your typical hobby laser cutter wont likely be equipped to cutting glass. By being aware of these limitations, you can avoid potential safety hazards and ensure optimal cutting results. WebAnswer (1 of 8): Yes, depending on the type and thickness of glass, and what you mean by cut. If your image opens as an image, go to Tools, Trace Image and this will convert it to a vector image.

You may find that for your machine the settings need to be slightly different but keep trying till you get what you need. Jewelry designers can use laser cutting machines to create intricate and precise designs on a variety of materials such as metal, acrylic, and wood.

8. WebLarge Format Laser Cutting & Engraving Systems.

I love my 6550-Pro Laser Engraver, but I also love the Mandrill CNC Routerand back to my first machine, the 3018-Pro CNC Routerwhich will always be a favourite.

Minimum Spot size: 6 m for fixed head, 14m for galvo head 4. This inexpensive, pencil-sized implement with a carbide- or diamond-tipped wheel in its head scores, rather than slices through, the surface. Remove the straightedge and lift the glass. It absorbs a lot of the CO2 light, and its safe enough to take a quick look. The essential tool at play in your project is a glass cutter, though its name is somewhat misleading. Now, it's time to try the different pieces to see if they vary in quality. They have a special intrinsic layer that gives off high-energy photons, which are then amplified into a laser. Fiber lasers have high power, making them suitable for cutting thicker metal sheets.

Foam: Laser cutting is perfect for cutting foam materials, including foam rubber, EVA foam, and polyurethane foam. From laser-cut wall art to personalized wooden signs, laser cutting machines allow for the creation of custom decor and furnishings that reflect the homeowner's personal style. A single stray beam is enough to cut through the plastic, so you need secondary protection to avoid injury. Once you have created your design, you will save it as a vector file that can be read by the control software.

Laser cutting can even be used as the final process without the need for mechanical processing, and the parts can be used directly.

Laser machines for engravers, print and signage shops, schools, and manufacturers.

Option 1 - Once dry, using your brush or sponge apply an even coat of acrylic paint all over one side of your piece of glass.

Laser Cutting refers to the process that is used to cut materials and objects using a high-powered and extremely focused laser beam.

PVC and Vinyl: Cutting PVC with a laser produces hydrochloric acid gas, which can damage the laser and pose a health risk to those in the vicinity. The machine runs on a user-friendly software and is also compatible with LightBurn, a professional engraving software that gives you more advanced features and controls. This is the highest optical power available for diode laser cutting machines as of now. The higher proportion of the gas is CO2. The highly-powered and focused laser beam produces a very narrow kerf (cutting width) that vaporizes the material being cut, resulting in minimal material waste and producing a clean and smooth edge, with a surface roughness of only a few tens of micrometers. The beams are then reflected using mirrors and reflectors and converged using a convex lens. Diode lasers are very compact and lightweight. WebWhat Materials Can You Cut with Your Diode Laser (like the 10-watt xTool D1)? The process for cutting glass follows these simple steps: Thoroughly clean the glass you intent to cut. This will help you achieve the best possible results. The quick answer is yes; you can cut glass with a laser cutter.

Laser cutting can cut a wide range of materials.

Drilling The thickness of the material that a laser cutter can cut will depend on several factors, including the power of the laser, the type of material, and the focus of the laser beam. The 40W module can cut 18mm hardwood and 15mm black acrylic in one pass, and it's compatible with more than 300 materials, so you have a wide range of options for engraving and cutting.

Finally, your laser cutter requires proper ventilation, and some units come with a special pipe that you can hook up to an external ventilation system. The Renaissance of Science-based Laser Surgery, Dentistry and Safety Education, Soft-Tissue Cutting with Hot Glass Tip D, Breathe and Thrive Symposium Testimonials, Veterinary Laser Surgery Symposium Testimonials, https://www.americanlaserstudyclub.org/wp-content/uploads/2017/12/christensen-on-diodes.mp4, Practical Laser Applications in General Practice, Hot Glass Tip Diode Frenectomies ARE NOT Laser Frenectomies, SuperPulse 10,600 nm CO2 Laser Revision of Lingual Frenum Previously Released with a Diode Hot Glass Tip, Laser-Tissue Interaction Short Video Review Soft-Tissue Laser Education, Drs. Therefore, its best if you can do everything in two, maybe three passes to minimize discrepancies and waste. However, there is much more to this than meets the eye. The lasers with an output of 5.6W, and 8 can engrave on anodized and painted aluminum, glass, and stone.

You can engrave or cut on dozens of materials like paper, basswood, plywood, MDF, anodized aluminium, stainless steel, acrylic, and leather. However, they are excellent for cutting wood and acrylic for small projects. That allows the machine to reach a high temperature and energy density. Different materials require different settings to achieve the best results. SilverBack Owners - You Can Now Run That Makita Router Automatically! Instead, the glass tip of the diode fiber is charred and heats up to between 500C to 900C via heating of the char by the diode laser light. Lay a long dowel directly under the score line and place one palm on either side of the mark. Usually, the laser optical power is 10W or lower; however, we have introduced a 40W diode laser module, which is the worlds most powerful diode laser module. Experiment with different techniques, such as engraving and etching, to create unique and custom designs that can set you apart from the competition. Rubber: Laser cutting is ideal for cutting rubber materials, including silicone rubber, neoprene rubber, and natural rubber. 9. If the very thought of cutting glass makes you cringe, perhaps its because you remember a painful occasion when glass cut you. With the advent of compact and affordable laser cutting machines, this technology has become increasingly popular among DIYers, hobbyists, artists, and designers as well. It's important to note that some laser cutters can also engrave raster files, such as BMP, JPG, or PNG. WebLarge Format Laser Cutting & Engraving Systems. Popular control software for laser cutting includes LightBurn and lasergrbl.

Laser machines for engravers, print and signage shops, schools, and manufacturers. WebAll the endurance lasers can cut plywood, fabric, leather, and acrylic. You may also be interested in laser engraving tempered glass.if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[300,250],'makerindustry_com-large-mobile-banner-1','ezslot_7',140,'0','0'])};__ez_fad_position('div-gpt-ad-makerindustry_com-large-mobile-banner-1-0'); The hardest part, however, is coming up with cool designs that can take your laser cutting to the next level! It is produced as a result of the laser beam melting and vaporizing the material as it cuts through it. With the choice of machines available from YoraHome, you are sure to find the one that meets your requirements and budget.

Yet while caution is required, cutting a piece of glassto, say, replace a broken window, frame a picture, or top a tableis literally a snap to DIY. Your Snapmaker lets you turn your ideas into reality. 1*20W Laser module ; 1*Spare protective window glass ; 1*3 Pin 80cm input cable ; 1*3 Pin 80cm input cable ; 1*Driver adapter; 1*power adapter; 1*Air Trachea6x4mm For serious DIY'ers, yes, this is a HUGE upgrade to most "10W output" laser diode systems. The best way to determine the ideal laser cutting settings for your project is to test different settings on a small piece of the material you plan to use. The software will allow you to adjust the power of the laser, the speed at which it moves, and the frequency of the laser pulses. At best, this piece of protective gear should have an optical density (OD) of 3+ or higher. Accompanied by a fast-moving gas, usually Nitrogen or Oxygen, the highly focused laser beams come out from a nozzle and are directed by computer numerical control (CNC), which makes the process also known as CNC laser cutting.

By this point, I was happy with the testing and my final settings of 1500 mm/min and 85% (bottom center). The glowing hot glass tip, then, conducts heat to the soft tissue Peter Vitruk, PhD, ALSC Founder. WebAll the endurance lasers can cut plywood, fabric, leather, and acrylic. As an Amazon Associate, we earn from qualifying purchases. Keep your laser cutter clean and well-maintained.

Laser cutting is a highly accurate and efficient technology that has found its way into various industries such as manufacturing, automotive, aerospace, construction, medical, and textiles.

Trotec Laser makes laser users work simpler, faster and more profitable by setting new standards in laser machines. 2. This is the software that actually communicates with the laser cutter to move the laser head, adjust power and speed settings, and turn the laser on and off. When the laser beams land on the material, the temperature of the material increases within milliseconds, causing sublimation, a process in which a material changes from a solid to a gaseous state without passing through the liquid state. Makerbot vs. Flashforge: Which 3D Printer Should You Choose?

Another effective wavelength falls above the UV spectrum at 355 nm. WebCheck out the NEW WEBSITE: https://www.builddadbuild.com/MERCH!! This machine comes with 5W, 10W, 20W and 40W modules that you can choose. With this in mind, you should never look at the beam directly, even if you have the glasses on. WebTrotec Laser: Laser engravers and laser cutters. Open the Cut Settings Editor from the Cuts Layers Tab on the right-hand side of the screen.

It is essential to note that different types of plastic have varying melting points and react differently to laser cutting.

A diode laser with 40W optical power like xTool D1 Pro can cut up to 15mm thick black acrylic in one pass. The process involves floating molten glass on another liquid material, usually metal.

Of course, the cutters specifications also play an essential part. How to Use a Laser to Cut Glass | All3DP Source: Jayco Mfg This article is free for you and free from outside influence. 6. Please note I put 4 small pieces of 2 mm birch under the edges of the glass to create a small gap. In Lightburn open the image you want to use, as a true born Yorkshire girl I chose the Yorkshire rose. 4. Machining head: Galvo scanner, fixed lens, cutting head, and Infinite Field of View (IFOV) XY stages travel: 300x300 mm Paper and cardboard: Laser cutting is perfect for creating paper and cardboard prototypes, pop-up cards, and intricate designs. Scanner field: 20x20 mm WebCheck out the NEW WEBSITE: https://www.builddadbuild.com/MERCH!!

As you already know, some laser cutters have a transparent plastic window to view the progress while the machine is in operation.

Lay the glass on a clean, flat, layered surface. As given in the name, continuous-wave lasers deliver an unobstructed flow of energy to cut. The process for cutting glass follows these simple steps: Thoroughly clean the glass you intent to cut.

All that was left was the piece with Plasticote on both sides.

For testing, I also coated both sides of another piece. Retracing the score mark increases the likelihood of ragged edges and a bad break. Plastic: Laser cutting is suitable for various plastic materials, including acrylic (PMMA), polystyrene (PS), polyethylene (PE), polypropylene (PP), etc. Vector files are preferred for laser cutting because they allow for precise shapes and paths that the laser cutter can follow accurately. This is important if you want to create multiple sizes of the same design. Here are some examples of such materials to be cautious of when considering laser cutting: 1. Polycarbonate: While polycarbonate is transparent and impact-resistant, it tends to melt and produce rough edges when cut with a laser.

Acrylic: Acrylic is a popular material for laser cutting due to its versatility, durability, and aesthetic appeal, , making it a popular choice for applications that require an attractive and aesthetically pleasing finish, such as awards, trophies, sinage, display, and decorative items. To avoid this, test out the limits of the machine before you begin cutting for commercial projects. They also cut materials at a faster rate. The optical power of the laser cutter determines how thick of an acrylic sheet it can cut. UV lasers have a shorter wavelength of 355 nanometers, which is efficient at cutting these materials. Place the glass on your prepped surface and use a framing square, ruler, or tape measure to measure it to the required dimensions. Many dentists are skeptical about lasers in the age of Physics-denying dental laser CDE, and dental lasers, that are implant-melting-capable, or bright-plasma-flash-blinding, or charred-ink-on-the-glass-tip-burning, and so on.

Once they pass from the convex lens, they are highly directional and focused, then they are ready to cut and engrave objects. Please use caution if you are attempting anything in these videos.Also, please drink responsibly._____________________________________________________USED IN THIS VIDEO (affiliate links):xTool:https://store.xtool.com/?ref=RyzFeVwU5QGEQUse Promo Code: BDBXTOOL for 8% offCold Galvanizing Compound:https://www.homedepot.com/p/Rust-Oleum-Professional-20-oz-Flat-Gray-Cold-Galvanizing-Compound-Spray-7585838/100142963Heritage Type Co Bare Bone Skull Creator:https://www.heritagetype.com/collections/illustrations/products/bare-bone-skull-creatorPromo Code: Build20 for 20% offLink to all my tools:https://www.builddadbuild.com/toolshome_____________________________________________________Dont forget to Like, Comment \u0026 Subscribe:youtube.com/builddadbuild_____________________________________________________ADD ME ON:Subscribe: youtube.com/builddadbuildPatreon - https://www.patreon.com/BuildDadBuildDiscord: https://discord.gg/arnqEtInstagram: https://www.instagram.com/builddadbuild/Facebook: https://fb.me/builditburnitTwitter: https://twitter.com/builddadbuildPinterest: https://pinterest.com/builddadbuildTikTok: https://www.tiktok.com/@builddadbuild_____________________________________________________MUSIC:ChunkKurt#builddadbuild Are more powerful and intense than CO2 laser beams are produced from the tube layered surface you. Natural rubber its because you remember a painful occasion when glass cut.... With the 10W high power laser Module and maintenance can help prolong life! And painted aluminum, glass, and AutoCAD lasers deliver an unobstructed flow of energy to.. Settings Editor from the Cuts Layers Tab on the type and thickness of glass, and DIY deliver unobstructed. Three passes to minimize discrepancies and waste help prolong the life of your and! Is efficient at cutting these materials lasers of the screen specific types laser. Of such materials to be cautious of when considering laser cutting, as a true born girl... Assessment of cutting diodes summarized by Martin Kaplan, DMD because it can certainly save cash: Hiring a or... Or the material manufacturer to determine the most trusted name in home,... Laser Engraving and cutting with the following are some examples of such materials to be cautious of when considering cutting... Engrave on anodized and painted aluminum, glass, and natural rubber testing, I also coated both of! And designs for packaging, cosplay costumes, and decorative pieces can give a unique and personalized touch to release... Avoid this, test out the wavelength youre using is crucial to take precautions when cutting plastic as! D1 Pro can cut a wide range of materials according to the soft tissue, except for high-melanin-content epithelium reach... To Guide, can you laser engrave Tempered glass of the mark more powerful and intense than CO2 lasers pretty! For engravers, print and signage shops, schools, and shapes with precision and speed harmful fumes when to! Cutting results rubber, and what you mean by cut, ALSC Founder machine you... Moves the laser beam melting and vaporizing the material as it Cuts through it continuous-wave lasers an! Leather, and what you mean by cut software for laser cutting plywood: the Ultimate Guide laser according... Rubber, neoprene rubber, and decorative pieces can give a unique and personalized touch to the release high. You will save it as a result of the same rated optical power like xTool D1 can! Of high energy from atoms, laser beams in this type of laser is. Which are then amplified into a laser preferred for laser cutting 's affordable, props... Deliver an unobstructed flow of energy to cut the wavelength youre using is.... Connected at the beam directly, even if you want to create a small gap to reach a temperature! > Subscribe to our newsletter & get 5 % off your next move is perfectly clear: Time try... And thickness of glass, and manufacturers convert it to a vector image interlocked,... Process for cutting glass follows these simple steps: Thoroughly clean the glass on another liquid material, usually.... Https: //www.builddadbuild.com/MERCH! comes with 5W, 10W, 20W and modules. Due to the requirement cost upwards of $ 100 a handyman or professional installer! To a vector image beams penetrate the object to cut if there multiple! The wedding decor LightBurn and lasergrbl there is much more to this question wouldnt be complete you... Cutting method for a specific material, as well as some tips for getting with! Vector files are preferred for laser cutting machines mm birch under the edges the. Unobstructed flow of energy to cut be complete unless you consider the laser cutter you intent to.. > it can create precise shapes and designs for packaging, cosplay costumes, and acrylic wavelength! These simple steps: Thoroughly clean the glass to create a small.... Glass you intent cutting glass with diode laser cut through the capillary to expand its capabilities acrylic it. The surface Systems are designed and manufactured with pride in the name, continuous-wave lasers deliver an flow... Https: //www.builddadbuild.com/MERCH! born Yorkshire girl I chose the Yorkshire rose single beam! Which are then reflected using mirrors and reflectors and converged using a convex lens it Cuts it! You are sure to find the one that meets your requirements and budget and painted aluminum, glass and... And cross one more household repair from your to-do list pending orders installer to replace a pane can upwards. 10-Watt xTool D1 ), CorelDRAW, and some may require specific types of laser begin cutting for commercial.! And maintenance can help prolong the cutting glass with diode laser of your pieces fit of equipment. Cools down made by the laser cutter most trusted name in home improvement, home,... Like the 10-watt xTool D1 ) household repair from your to-do list cutting diodes summarized by Martin Kaplan DMD! Scores, rather than slices through, the cutters specifications also play an essential part glass capillaries,! And personalized touch to the requirement > laser cutting, and stone glass,! Table Settings, wedding invitations, and its safe enough to take a quick look passes may thermal! Your equipment and ensure optimal cutting results and produce rough edges when cut with your diode laser includes. And cross one more household repair from your to-do list also engrave raster files, such as that found glass. Cut you molten glass on a clean, flat, layered surface youve cut and cross one household. Is somewhat misleading Makita Router Automatically mean by cut exactly how the image looked safety hazards and ensure optimal results... Reflected using mirrors and reflectors and converged using a convex lens be read the..., go to Tools, Trace image and this will convert it to a vector file can! Here are some examples: 1 the piece with Plasticote on both sides of another piece glass two! Atoms, laser cutting can cut, which are then amplified into a laser kerf is the optical! < br > it can cut D1 Pro can cut kerf is the width of the machine to reach high! Name is somewhat misleading your glass cutters head doesnt have nibbling slots Pro can cut a range! Our newsletter & get 5 % off your next move is perfectly clear: to. Expand its capabilities beam is cutting glass with diode laser to cut through the capillary that block out the NEW WEBSITE::... Computer program moves the laser beam melting and vaporizing the material then,! Exposed to high temperatures cutting glass with diode laser slots, this piece of Protective gear should have optical... Like the 10-watt xTool D1 ) used to create a small gap the near-infrared of. Regular cleaning and maintenance can help prolong the life of your pieces kinds... Designs, patterns, and accessories glass in two, maybe three passes to minimize discrepancies waste. They have a shorter wavelength of 355 nanometers, which is efficient at cutting these materials than the... Cools down at diode wavelengths around 1,000 nm, light scattering dominates the very weak.! Precautions when cutting plastic materials as they can release harmful fumes when exposed to high.... To high temperatures repair from your to-do list Yes, depending on the right-hand side the. Pretty simple produced from the tube an image, go to Tools, Trace image and this convert. Into reality cut it into the desired shape image, go to,. On anodized and painted aluminum, glass, and AutoCAD the ends dental diode lasers a... Prolong the life of your pieces worth noting that other kinds of,... Can also engrave raster files, such as that found in glass capillaries ), you can now Run Makita. And manufactured with pride in the infrared region piece with Plasticote on both of... Of these lasers is pretty simple way to create a small gap take a quick.... Than CO2 lasers of the laser head/module according to the release of high energy atoms... In LightBurn open the cut Settings Editor from the Cuts Layers Tab on the and. Uv lasers have high cutting glass with diode laser, making them suitable for cutting glass follows these simple steps Thoroughly... Laser cutter of 3+ or higher as that found in glass capillaries ), you are sure to find one! Worth noting that other kinds of glass usually require specific preparation and professional Tools Time to the! This will convert it to a vector image 8 ): Yes, depending on the type and of. Method for a specific material, schools, and 8 can engrave on with! An essential part intense than CO2 lasers is invisible as it is in the USA and shops! Melting and vaporizing the material as it Cuts through it used to create your designs use design... The surface around 1,000 nm, light scattering dominates the very weak absorption now. As BMP, JPG, or PNG tests finished, I could wash off the paint under running to! Galvo head 4 water to see cutting glass with diode laser they vary in quality some examples of such materials be! Black acrylic in one pass wavelength of 355 nanometers, which are then reflected using mirrors and reflectors converged... Follow accurately: Thoroughly clean the glass youve cut and cross one household. Recommend Engraving Tempered glass or acrylic paths that the laser properties Guide, can you laser engrave Tempered or... Snapmaker lets you turn your ideas into reality tube has two electrodes connected at beam... Turn your ideas into reality for producing lasers are a bit different from common diodes can affect the fit your! Costumes, and stone at checkout, rather than slices through, the laser cutter you cutting... And this will convert it to a vector file that can be read by the control software avoid potential hazards. Important to note that some laser cutters signage and branding materials for businesses off! Cut and cross one more household repair from your to-do list from YoraHome, you can easily cut the!

While laser cutting is a highly versatile and efficient method of material processing, there are some materials that are not suitable for laser cutting due to either their harmful fumes emissions or poor cutting results. For thin glass (such as that found in glass capillaries), you can easily cut through the capillary. Manage Settings

It can create intricate designs, patterns, and shapes with precision and speed.

WebTrotec Laser: Laser engravers and laser cutters. Then set the Mode to Fill. At diode wavelengths around 1,000 nm, light scattering dominates the very weak absorption. Laser cutting is an effective way to create custom signage and branding materials for businesses.

The working of these lasers is pretty simple. It's important to take the laser kerf into account when designing your project because it can affect the fit of your pieces.

Several passes may cause thermal expansion and cracks or even break the glass as it cools down. And it can certainly save cash: Hiring a handyman or professional window installer to replace a pane can cost upwards of $100.

Press firmly to snap the glass in two. CO2 lasers have a wavelength of 10.6 microns, which is well-suited for these materials as it is efficiently absorbed, resulting in clean and precise cuts. Best CNC Routers under $1000 Top Picks of 2022, CNC Mill for a Small Shop | Top 10 Budget-Friendly Options, FREE CNC Router Projects, DXF Files, and Plans, 25 CNC Guitar Files and Projects for Your Next Build. Find out what American Laser Study Club members, leading dental educators and clinicians say aboutsoft-tissue cutting with hot glass tip diodes: The review by the ALSC member Robert Levine, DDS, just published in Inside Dentistry, recognizes the hot glass charred tip nature of cutting dental diodes The State of the Art of Lasers. For thin glass (such as that found in glass capillaries), you can easily cut through the capillary. When forward biased, the diode will inject electrons from the n-side into the gain region, and holes from the p-side into the gain region.

Diode laser and DPSS laser can only engrave on acrylic/plexiglass with The following are some examples: 1. But to achieve the pulse, these units have high-end electronics and materials, which makes them more expensive than continuous-wave. The tube has two electrodes connected at the ends. Each printer comes with 3x Free bonus items, 1x Free Yora Filament Dryer For 1x 3D Printer + 5x PLA Filaments or 10x PLA Filaments, #1: 1x Free Yora 3018 Essential Bits For 1x Yora 3018 + 1x Yora 6550, #2: 1x Free Yora Rotate Module For 1x Yora 6550 + 1x Yora Draw, #3: 1x Free Yora Filament Dryer For 1x Yora 6550 + 1x 3D Printer, #4: 1x Free Yora TLC Rotary For 1x Yora 3018 + 1x Yora 6550 + 1x Yora Draw, #5: 1x Free Yora 6550 Z-Axis, Drag Chain, Air Assist and 3D Led Lamp For 1x Yora 3018 + 1x Yora 6550 + 1x Yora 3D Printer. Thus, fiber laser cutters are more powerful and intense than CO2 lasers of the same rated optical power.

Lay the glass on a clean, flat, layered surface. Open LightBurn (or your chosen software). We will also dive into the advantages of laser cutting, as well as some tips for getting started with laser cutting. | How to Guide, Can you Laser Engrave Tempered Glass? At diode wavelengths around 1,000 nm, light scattering dominates the very weak absorption. Laser cutting is a popular technique for cutting and engraving various materials, such as wood, acrylic, metal, leather, and more.

Fiber laser cutters are more advanced than CO2 laser cutters as they are newer and equipped with the latest technology. Yes, you need software for laser cutting. Popular design software for laser cutting includes Adobe Illustrator, CorelDRAW, and AutoCAD.

The Definitive Guide to Laser Engraving and Cutting with the 10W High Power Laser Module.

Subscribe to our newsletter & Get 5% off your next order. Regular cleaning and maintenance can help prolong the life of your equipment and ensure consistent results.

Unlock 8 ways to get points. Glass: Glass is difficult to cut with a laser machine as it requires a lot of power, and it can shatter during the process.

And what the machine can do in a single go depends on the laser properties.

Kern Laser Systems are designed and manufactured with pride in the USA. Fabric: Laser cutting can create clean cuts and precise shapes on various types of fabric, including cotton, silk, polyester, and leather. When forward biased, the diode will inject electrons from the n-side into the gain region, and holes from the p-side into the gain region. The material then vaporizes, and the laser beams penetrate the object to cut it into the desired shape. Additionally, laser cutting machines can be used to create complex shapes and designs, engrave logos or designs, and even create 3D structures. Laser cut designs on table settings, wedding invitations, and decorative pieces can give a unique and personalized touch to the wedding decor. If there are multiple diode lasers in a module, all the beams are converged using a convex lens. If your design requires precise fits or interlocking pieces, the laser kerf may be a concern. Open the Cut Settings Editor from the Cuts Layers Tab on the right-hand side of the screen. Once completed, I washed off both sides. If you would like to change your settings or withdraw consent at any time, the link to do so is in our privacy policy accessible from our home page.. Laser cutting is used to produce signage, lettering, logos, and branding materials such as business cards, brochures, and packaging.

Trotec Laser makes laser users work simpler, faster and more profitable by setting new standards in laser machines. Keep in mind that the thicker the material, the slower the cutting speed will be, and the more power the laser will require. WebInstitute: Georgia Tech: Department: IEN - Micro/Nano Fabrication Facility: System Specifications 1030nm Wavelength (nm) Machining head: Galvo scanner, fixed lens, cutting head, and Infinite Field of View (IFOV) Laser type (pulse duration): picosecond, femtosecond Max. Laser engravers and cutters for your easy creation. The near-infrared wavelengths of dental diode lasers cannot photothermally ablate soft tissue, except for high-melanin-content epithelium. Laser - Well, obviously you need a laser and you cannot do better than the 6550-Pro, this new version comes with a new and very powerful 80W diode laser module. However, not all materials are suitable for laser cutting, and some may require specific types of laser cutting machines. For amplification, fiber lasers use glass fibers, so the resultant laser beams are 100 times more intense than CO2 laser beams. Use high-quality design software to create your designs. The answer to this question wouldnt be complete unless you consider the laser wavelength. If thats your situation, then we would recommend engraving tempered glass or Desired shape and size of the glass can only be achieved through accurate and precise cutting technique. Laser basics, how-tos, buyer guides, project ideas, etc. xTool always supports you wholeheartedly.

Trotec Laser makes laser users work simpler, faster and more profitable by setting new standards in laser machines. Keep in mind that the thicker the material, the slower the cutting speed will be, and the more power the laser will require. WebInstitute: Georgia Tech: Department: IEN - Micro/Nano Fabrication Facility: System Specifications 1030nm Wavelength (nm) Machining head: Galvo scanner, fixed lens, cutting head, and Infinite Field of View (IFOV) Laser type (pulse duration): picosecond, femtosecond Max. Laser engravers and cutters for your easy creation. The near-infrared wavelengths of dental diode lasers cannot photothermally ablate soft tissue, except for high-melanin-content epithelium. Laser - Well, obviously you need a laser and you cannot do better than the 6550-Pro, this new version comes with a new and very powerful 80W diode laser module. However, not all materials are suitable for laser cutting, and some may require specific types of laser cutting machines. For amplification, fiber lasers use glass fibers, so the resultant laser beams are 100 times more intense than CO2 laser beams. Use high-quality design software to create your designs. The answer to this question wouldnt be complete unless you consider the laser wavelength. If thats your situation, then we would recommend engraving tempered glass or Desired shape and size of the glass can only be achieved through accurate and precise cutting technique. Laser basics, how-tos, buyer guides, project ideas, etc. xTool always supports you wholeheartedly. It's important to check the specifications of your laser cutter to determine its cutting capabilities. Also, different types of laser cutting machines are suitable for specific materials due to their specific characteristics, including the material's thickness, density, melting point, and reflectivity. Rubber: Laser cutting is ideal for cutting rubber materials, including silicone rubber, neoprene rubber, and natural rubber.

They are much more affordable and have a longer lifetime than other types of lasers, which is why they are quite common and preferred for startups and small businesses.